Beschrijving

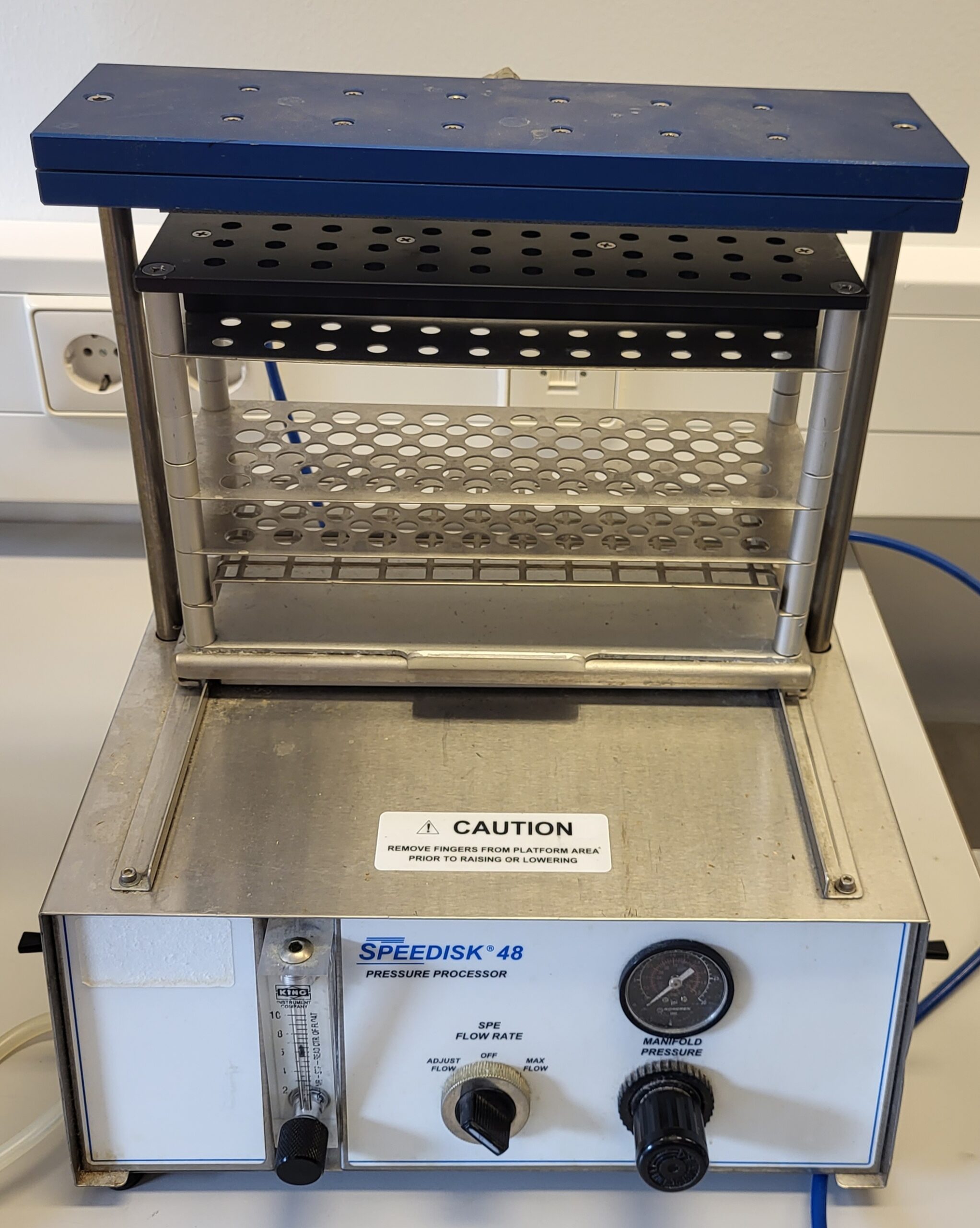

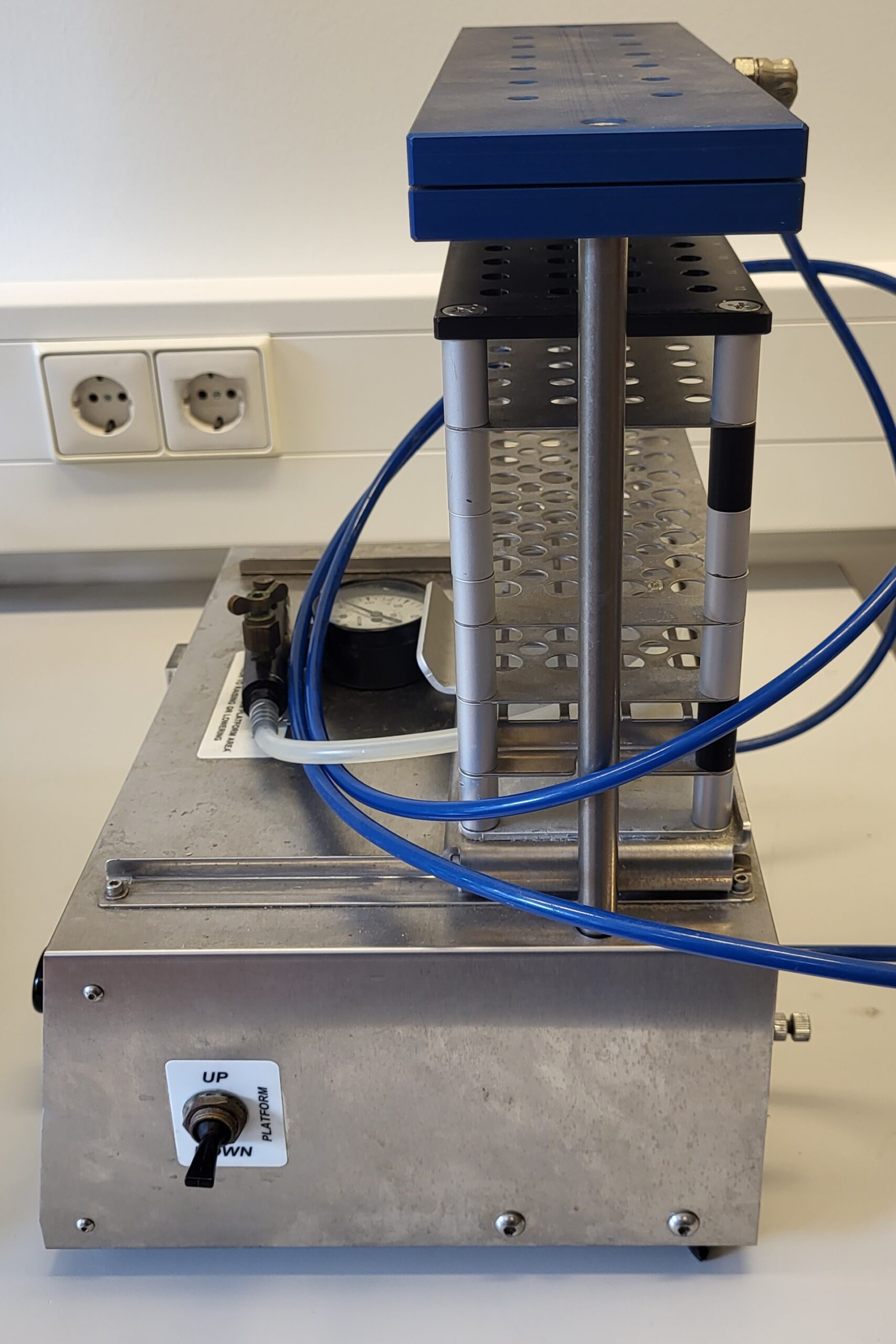

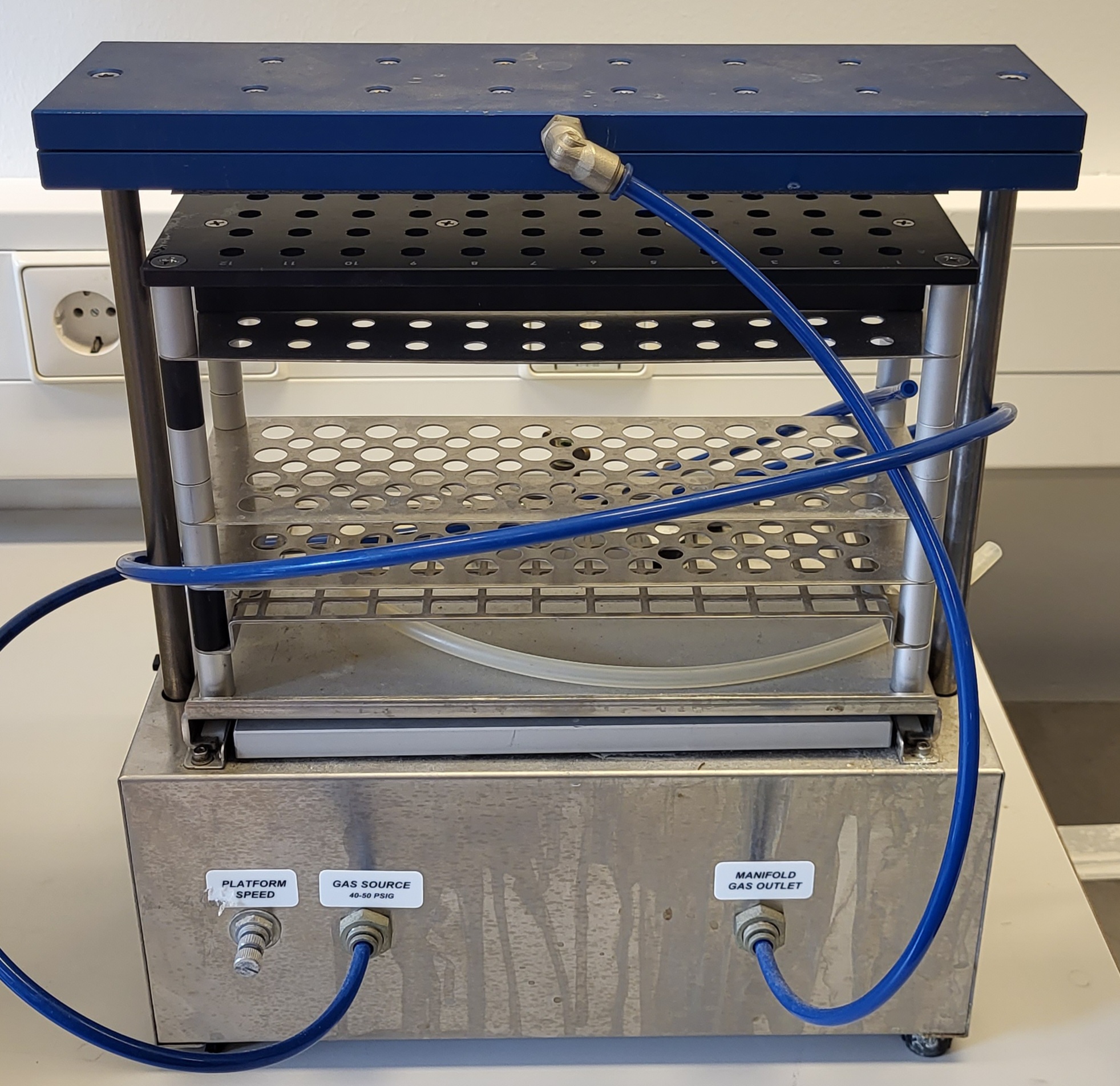

Tweedehands Speedisk 48 Drukprocessor Tweedehands Speedisk 48 Drukprocessor Used Speedisk 48 Pressure Processor The Speedisk 48 pressure processor is designed to process 1, 3 and 6 ml SPE columns in batches of 1 to 48 samples. The columns are placed under the pressure processor manifold where an inert, dry gas simultaniously and uniformly displaces the liquid that was pipetted down each column.

Pressure processing has many advantages over traditional vacuum processing:

Higher pressure differentionals are achievable to overcome resistances to flow caused by high viscosity.

Gas distribution through the manifolds ensures uniform pressure and uniform liquid flow at each SPE tube, even when some positions are open. That enables reproducible SPE runs column to column.

Liquid flow rate changes quickly and proportionatly when gas pressure is changed.

Blow-down and drying with N2 can be performed in place.

An dry, inert gas can be used for processing.

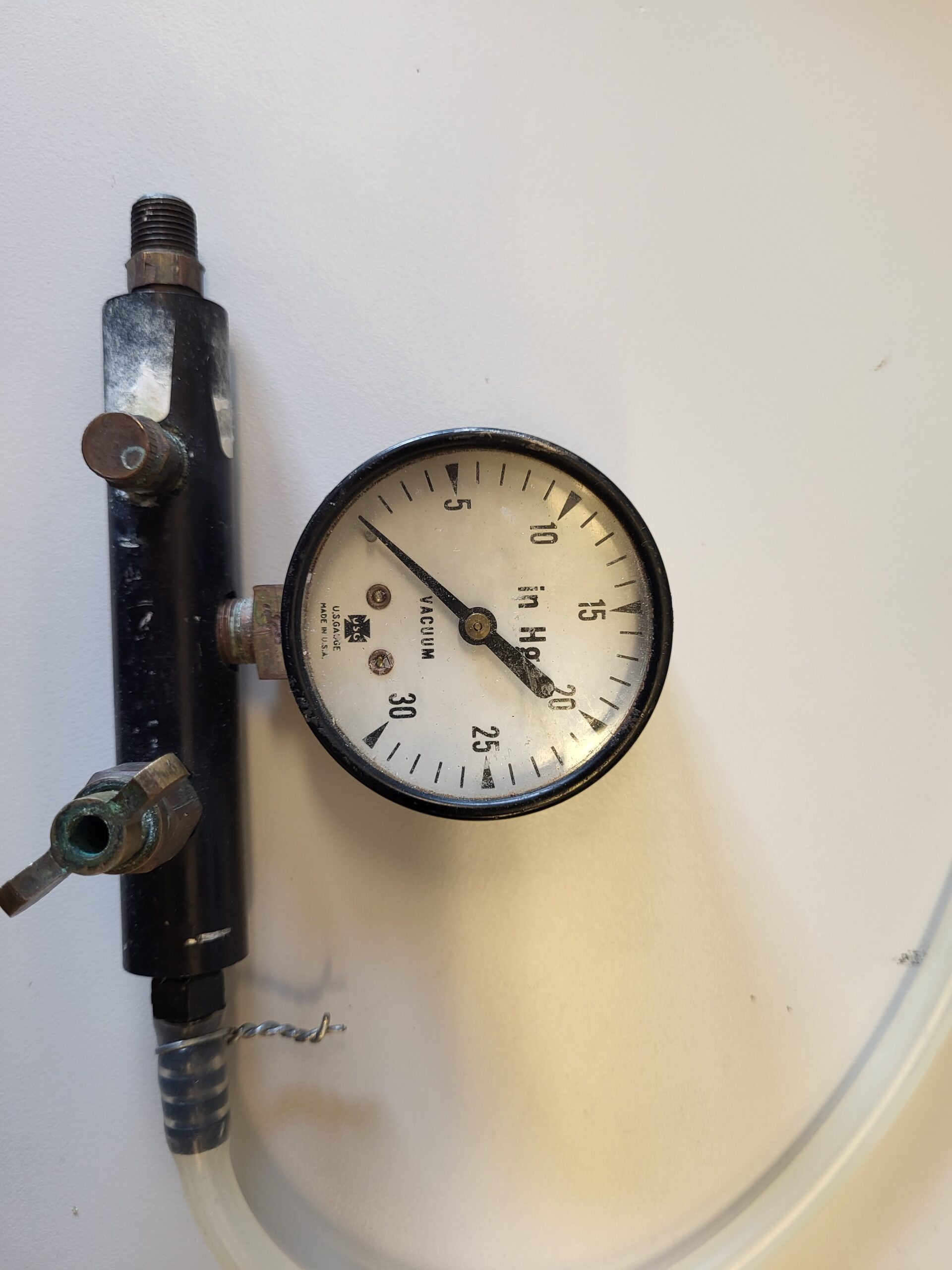

The manifold pressure gauge on the machine is broken, which is why an extern pressure gauge is delivered with the machine.